Unit Deinventory System

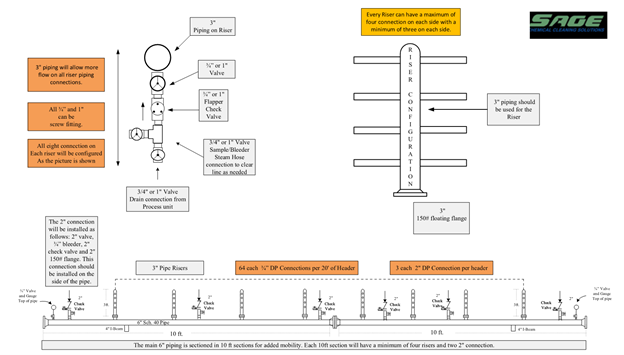

- Unit drain header piping system that is customizable to suit each individual project

- The system collects all waste streams(liquid and vapor) in our specially designed piping to prevent accidental atmospheric releases.

- Compliant with most facility’s MOC requirements

- Designed to allow connections of ¾”, 2” ,3”,4”,6” low point drains of towers, drums and exchangers

- Cleanout valves installed on the ends of all manifolds for final clean out prior to removal

- Isolation valves are installed throughout according to the timeline supplied by the plant. The purpose is to allow removal of manifold sections prior to completion.

- Pressure gauges are installed throughout the manifold.

- Condenser collapses and/or condenses steam into a pumpable effluent

- Special self-contained effluent pumps are installed

- Surge tank can be installed for larger project at aid in effluent disposal

A dual high-temperature air operated diaphragm pump is installed to allow the condensed effluent to be pumped to refinery tankage.

Contact a Sage Chemical Cleaning Solutions and Decontamination expert today! To learn more, please call (833)SAGECLN (833)724-3256 or email us at info@sageccs.com.