- Sage Chemical Cleaning and Decontamination’s team uses an analytical laboratory capable of: measuring deposit density, identifying deposits, testing solvents & recommending procedures, and performing post-cleaning analysis of drain samples.

- Our experienced team has full capability to handle jobs of any size, also incorporating:

- Specialized Pumps, Hoses, Manifolds

- Unit deinventory effluent system (piping, hoses, coolers, filters, tanks and pumps)

- Trademarked Chemistries

- Sizable experienced technical support staff, i.e., Process Specialists, Project Managers, Chemists, Service Supervisors.

- Total (local & national) company resources that can be drawn from to support large projects.

- Project management capacities include:

- Project timelines using Microsoft Project or Primavera

- Process flow diagrams using Visio

- Dedicated on-site Project Managers which work through all stages of cleaning procedure development

- Turnaround timelines

- Blind/Isolation Lists

- Instrumentation Isolation Lists

- Isometric Drawings for temporary piping

- Parts take off lists for temporary piping

- Detailed cleaning procedures

- Simplified drawings of equipment

- Process Safety Management Reviews

- Coordination of waste disposal for on-site and off-site requirements

- Turnaround Training to all personnel on chemical cleaning procedures

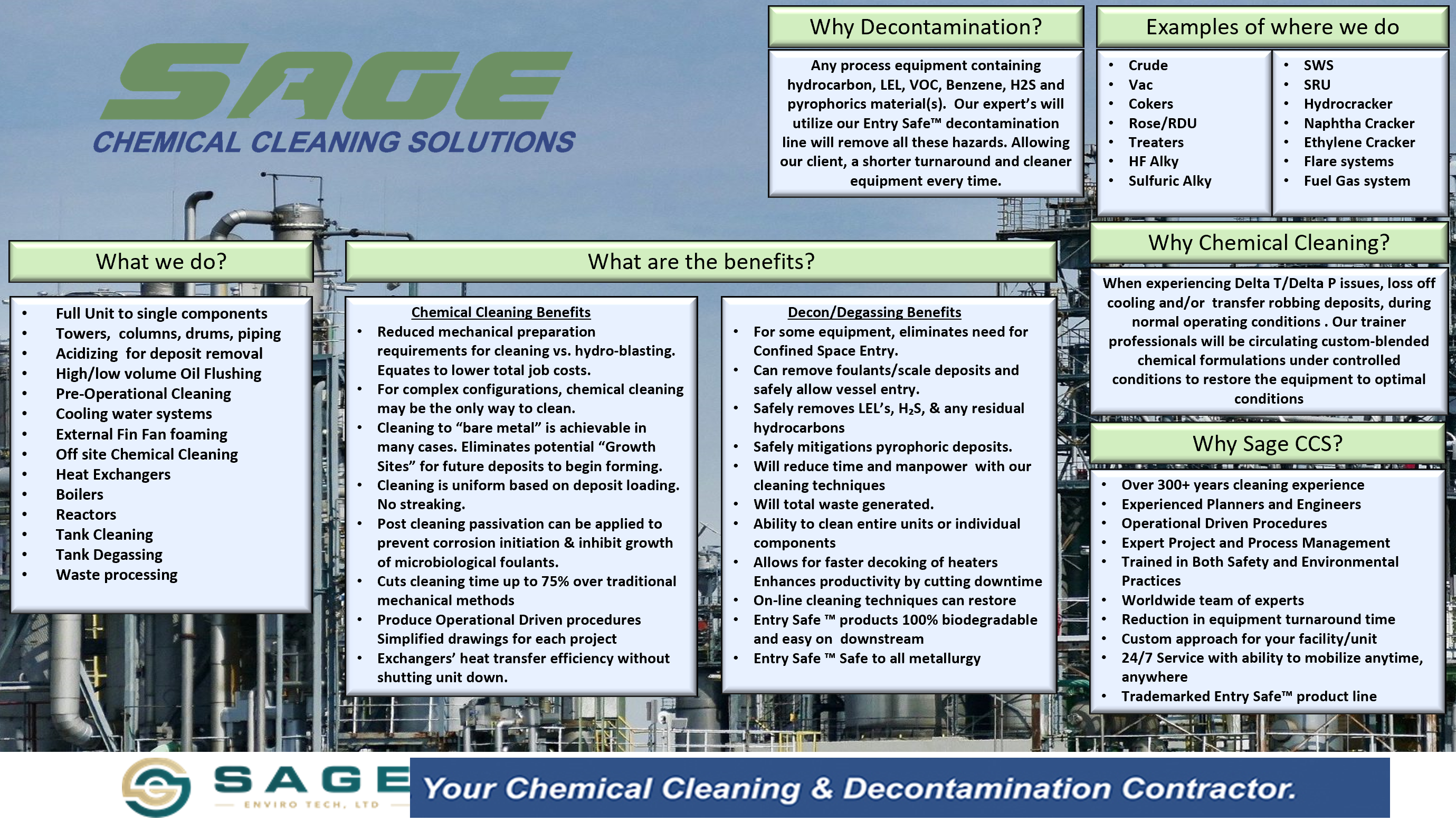

- Reduced mechanical preparation requirements for cleaning vs. hydroblasting, equating to lower total job costs

- For complex configurations, there may be no alternative to chemical cleaning

- For some equipment, our services eliminate the need for confined space entry

- Cleaning is uniformly based on deposit loading.

- Prevents corrosion initiation and inhibit growth of microbiological foulants

- Cleaning to “bare metal” is achievable in a large number of cases

- Eliminates potential growth sites for future deposits to begin forming

- Can remove foulants/scale deposits and decontaminates for later vessel entry

- Safe technique for pyrophoric deposit removal

- Can reduce total down time & waste generated via vapor phase, foam cleanings and on-stream applications, depending on equipment design and cleaning techniques

- On-Stream cleaning can restore exchangers’ heat transfer efficiency without shutting the unit down

Reactive Chemical Cleaning

Acidizing Cooling Water Equipment

- Piping, Coolers, Exchangers, pumps…

- Dissolve calcium carbonate and Iron Oxide deposits

- Return cooling water system to normal pressure and GPM within hours

Pickle and Passivation with Chelants (Citric, EDTA)

- Degreases and removes iron scales and passivation in one-step

- Reduces water by ⅔ and decreases time by ⅓

- System will be left neutral once circulation has been completed

- Examples: Package boilers, new equipment

Acidizing System with Mineral Acids (Hydrochloric, Sulfuric, Sulfamic, Formic, etc.)

- Rust and Calcium are the most common scale deposits removed by utilization of an acid wash

- System will be left neutral once circulation has been completed

- Examples: Cooler water, sour water strippers and liquor heaters

Additional Passivation Options of Metal Services

- Pickling is a metal surface treatment used to remove impurities, such as: stains, inorganic contaminants and rust or scale from ferrous metals.

- Pickling utilizes an organic or an inorganic acid to remove the contaminant.

- A passivation solution is utilized to convert the clean, active metal surface to a passive one. The surface is then resistant to after-rust.

- Additionally, passivation can refer to the deactivation of active corrosion sites on various alloys, and also to the elimination of polythionic species on alloys that would lead to potential corrosion.

Preoperational Cleaning

- Preoperational cleaning is required with new equipment to remove contaminants that would hinder the normal operation of the unit.

- Chemical companies usually utilize acids to fluidize the contaminants.

Online Chemical Cleaning

- Scale or contaminant removal completed by utilizing acid, solvent or a surfactant while the unit is running

- Gains 30-50% efficiency while only reducing production for a few hours

Exterior Fin Tube Cleaning/Foaming

- Can be completed while system is online

- Minimal mechanical configuration required (other than access to fins)

- Not fin tube damaging

- Spraying foam on the exterior surface of the fin tube to reduce surface tension which removes contaminants on the fins.

- Improved heat transfer as contaminants are removed

- Prevents fan stalling

Planning and Engineering for all Projects

- Management of both Sage and customer resources required to perform the chemical cleaning or decontamination process

- Sage provides on-site resources for technical needs relating to: mechanical preparation of equipment, waste effluent management, and coordination of adjacent tasks with the client’s team.

- Planning documents include, but not limited to: operationally driven procedures, scheduling, development of flow schematics (MSVISIO or Cad), mechanical needs, marked up P&IDs

Contact a Sage Chemical Cleaning Solutions and Decontamination expert today! To learn more, please call (833)SAGECLN (833)724-3256 or email us at info@sageccs.com.