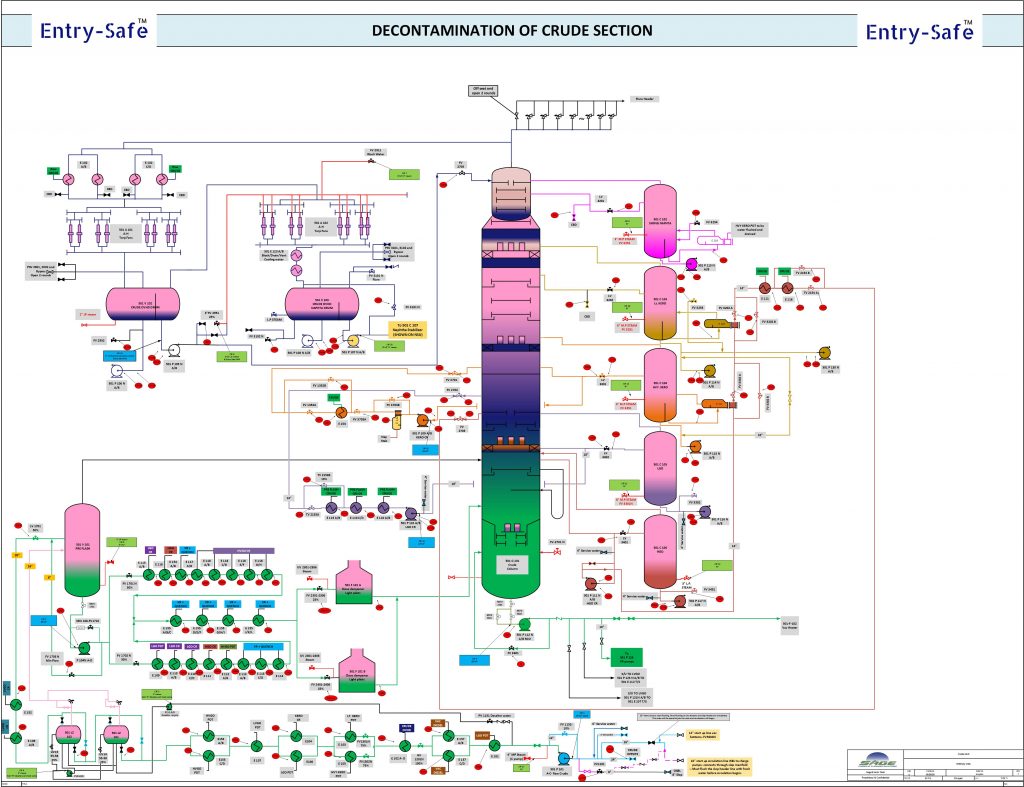

Vapor Phase Unit Decontamination

- Our process is designed for the removal of: light or heavy hydrocarbons, light ends, LEL, VOC, H2S, and for mitigation of pyrophoric materials.

- By injecting our Entry Safe ™ proprietary chemistry into the steam sources, our process atomizes and carries throughout the system.

- The surfactant package in the chemistry breaks the surface tension around the metal which allows the chemistry to penetrate and remove the trapped hydrocarbon.

- If H2S/Pyrophorics are present, Entry Safe™ Ox is used to treat and remove.

- This decontamination process reduces safety risks, equipment cleaning time and waste effluents. All of these combined efforts give our team (Sage/Customers) the desired outcomes for each task.

- Analytical labs are conducted throughout the process by pulling samples of the low and high point vents to determine when this process has been completed.

- Our process 100% saves time and money for our customers.

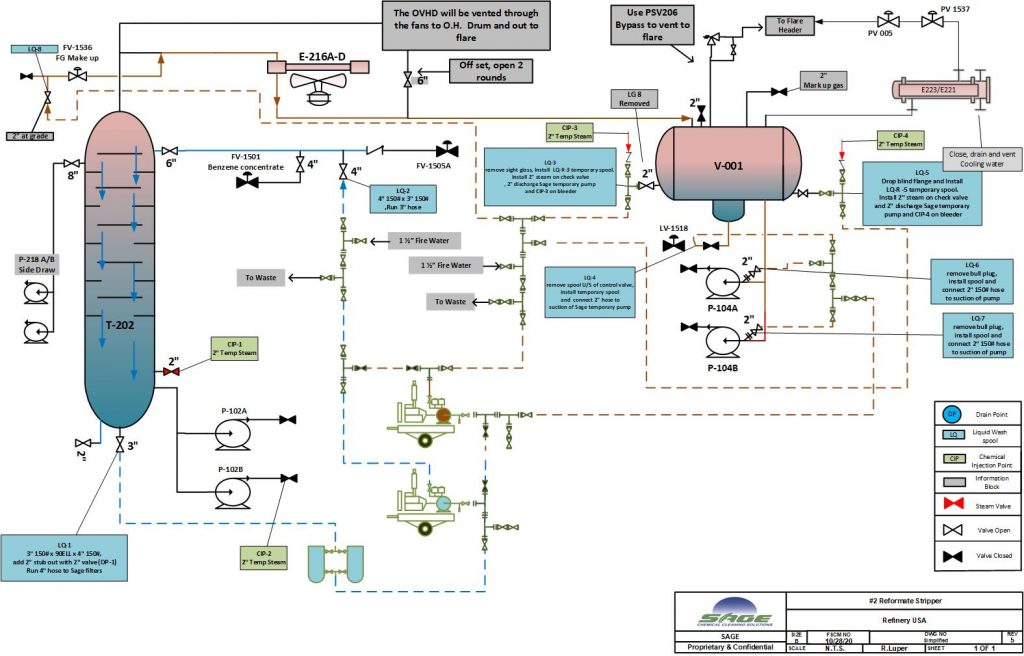

Liquid Circulation

- The liquid washing process is requisite when an NTE (not to exceed) temperature is found on equipment.

- If it is a heavy oil system, a cutter stock (LCO, Diesel) will be used and combined with our Entry Safe™ H.O.P. for asphaltenes fluidization.If the equipment is to be opened, it will require an additional step.

- The system would then be filled with freshwater and Sage Chemical Cleaning Solutions and Decontamination’s proprietary Entry Safe™ chemistry.

- Following, the component will be heated to the obligatory temperature and circulated.

- This process fluidizes and/or dissolves hydrogen-deficient hydrocarbon deposits from the equipment. Once fluidization is completed, maintenance vendors are able to open the equipment immediately for repairs.

- If pyrophoric material is present, Sage Chemical Cleaning Solutions and Decontamination would utilize oxidizer to render inert H2S and/or pyrophoric materials.

- A final flush with fresh water would then be required before the job is completed.

3-D Vessel Cleaning Nozzles

- When applicable, our specialty vessel cleaning nozzles are inserted into the target equipment.

- The 3-D vessel cleaning nozzles are specifically designed to minimize waste effluent and decrease cleaning time/costs for drums, vessels, and tanks.

- Cleaning diameters from 10ft to 250ft

Contact a Sage Chemical Cleaning Solutions and Decontamination expert today! To learn more, please call (833)SAGECLN (833)724-3256 or email us at info@sageccs.com.